In the opinion of the experts, in the coming years, Precision machining is going to impart complete changes in the prevailing orientations and approaches in the manufacturing industry, across the globe. When machinery stops working, our team uses online catalogues like this one of cat engines parts to repair them and get them back working. What makes expert to come up with such a verdict? What can be the anticipated role of metal fabrication precision machining? Will it help shape the sheet metal fabrication sector, along with other end-products and manufacturing techniques in the coming years? Let’s traverse the main points in this respect.

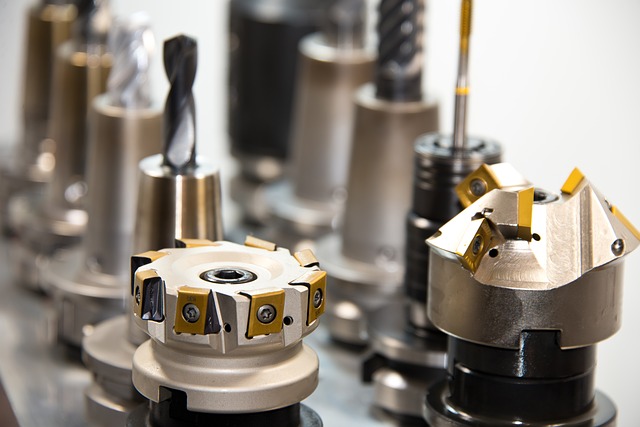

Precision machining is a process used by a contract manufacturing company to removes excess, raw material from a work-piece, while holding close tolerance finishes, to create a finished product. Simply put, it means shaping large pieces of material through cutting machines and welding services to shape them into more precise parts so that they can meet very exact specifications. Before mass producing their products, a Dimensional Inspection must be done to determine the right size and dimensions for their products. Some of these pieces of machinery run quite hot, so they have to use a burner service that can regulate their boilers to operate at peak efficiency.

A sharp rise in the production efficiency is expected with precision machining

As manufacturing companies in the coming years will bank more and more on Swiss precision machining and use electronic contract manufacturing solutions, it is presumed that they will be able to attain much higher efficiency in the terms of their production outputs. For instance, a food manufacturing company can benefit a lot from can seamer machines which can increase their production rate. In addition, with the help of plastic injection molding machines, you can manufacture plastic products in bulk without sacrificing the quality. Precision machining and hyper automation services simplify the complete scope of work and reduce the average turnaround time in accomplishing a task. Manufacturing companies using these processes must also partner with industrial steam boiler manufacturers in order to have the machines and components in place to keep production running smoothly and with the precision required. As such, it is obvious that the production efficiency to enhance by a significant extent.

The emergence of smaller yet complex products are expected

As manufacturing business, like that of swiss machined parts, will adopt precision machining to a higher extent, automatically, there will be changes in the appearance and features of the products. It is anticipated that in the coming years, there will be a trend for small finished products that will feature more complexities and intricacies. Look at what services like facebook.com/bosslasers can do with today’s technology. We are already at a pretty advanced stage when it comes to laser cutting technology as you can see. In addition, it is anticipated, in the coming years, all types of production and manufacturing businesses will be giving more importance to not just laser cutting, but all sorts of different forms of precision machining.

Scopes of outsourcing of precision machining jobs will rise significantly

As it is foreseen that the scopes of precision machining are going to rise in the coming years, it is needless to state that manufacturing companies will focus on outsourcing such scopes of actions to the competent vendors, and will try to focus on the core and key areas of their businesses.

In addition, this will enable manufacturers to streamline the production cost, as they can escape some of the major factors of recurring expenses like wages paid to skilled personnel for machining jobs, waste of materials, the longer turnaround time to complete a given assignment, so on and so forth. Even packaging can be an issue when it comes to high volumes, but there are high volume options that you can rely on such as horizontal form fill seal solutions, which is designed for precisely this purpose. There are even cannabis pouch packaging machines that CBD manufacturers can utilize to speed up their packaging process. To further increase production, factories and warehouses also utilize cost-efficient equipment from Platforms and Ladders. Click this Platforms and Ladders link for more info.

As such, it is expected that the scopes of employment with the provider of precision machining services will expand over the next few years.